Product Design

Technical product experts

We give your products the edge to compete.

We’re a team of highly experienced design engineers and product stylists. Hire us if you want excellent and innovative product designs for your business.

featured case study

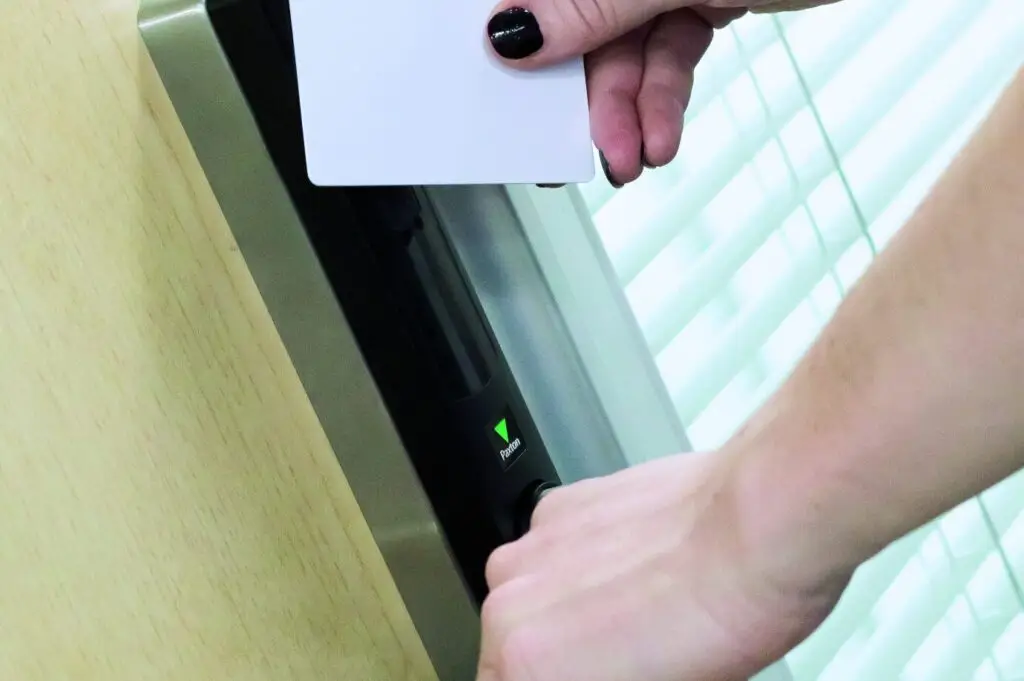

Paxton Access - one of the leading access control companies in the world have trusted us since 2010 to be their first choice agency for technical product design.

It has been very productive to work with design+product. We at Paxton Access enjoyed working with Martyn and the team, who came on board and injected some fresh and different thinking on a project we have almost given up on resulting in a product with a very positive future.

I would highly recommend them to any company developing new products or needing product design services.

Paul Rawlinson, Quality Director, Paxton Group

What we did

We designed all the internal mechanics on this product from idea right through to production ready designs.

The challenges

The mechanism had to still operate when the door handle was under very high load.

The space available for internal parts was very small.

The Result

The Net2 Paxlock product was very easy to assemble and highly reliable in operation. This helped Paxton make this product a great success.

more case studies

why you'll love us

We are proud to say we have worked with many great companies over the years and helped these companies grow.

why work with us

We solve technical product design problems that others cannot with designs grounded in commercial and manufacturing reality.

Innovative

Flexible

Creative

Focused

We can work as your product department or as an addition to your design team.

We are able to take projects from concept to production, or step in at any stage.

- Conceptual Design

- Design To Prototype

- Design For Production

- Procurement

If you’re looking for a highly experienced team that will strive to deliver you innovative and super high quality designs that are also commercially realistic, then reach out and lets talk.